Furniture pieces

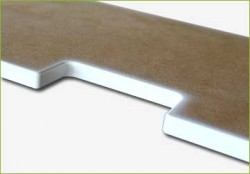

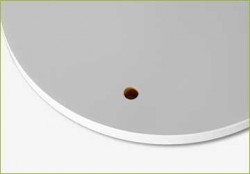

Automatic machining of tabular materials

The company Dřevotvar cooperative deals with the production of furniture components from large-surface material. This concerns exact blanks made from crude, laminated and veneered MDF or DTD.

Automatic machining means sizing, edge bending, drilling, grooving, CNC drilling and milling.

Capacity: 350 000 m2 pieces per year

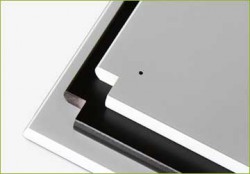

Surface treatment of tabular materials

Surface treatment consists in finishing of production of furniture pieces by varnishing by transparent or pigmented varnishes, or by mordanting. The company Dřevotvar uses the technology of rolling up or machine and manual spraying. Furniture pieces are mostly finished by water-based UV varnishes.

Capacity: 700 000 m2 pieces per year

Automatic machining of solid wood

Concerning solid o material, Dřevotvar often processes beech wood. Besides production of the assortment of small kitchenware, the production is also focused on furniture pieces. This mostly concerns solid table bases and stiles for cabinet and table furniture.

Surface treatment of solid wood

Solid pieces are most often surface finished by machine or manual spraying b standard varnishes and mordants. Soaking is also one of the commonly used surface treatment technologies in the company Dřevotvar.

Technologies (machine pool) for machining of tabular materials

CNC horizontal automatic separator saw

automatic edge bending machine

CNC woodworking centres

large-belt grinding machines

automatic drilling machines

Technologies (machine pool) for machining of solid wood

sizing saws

quadrilateral milling machines

multi-spindle drillers

copying milling machines

CNC, automatic and copying lathes

Technologies (machine pool) for surface treatment

rolling up line

spaying machine with UV tunnel for water-soluble coloured UV

spraying cabins

soaking lines